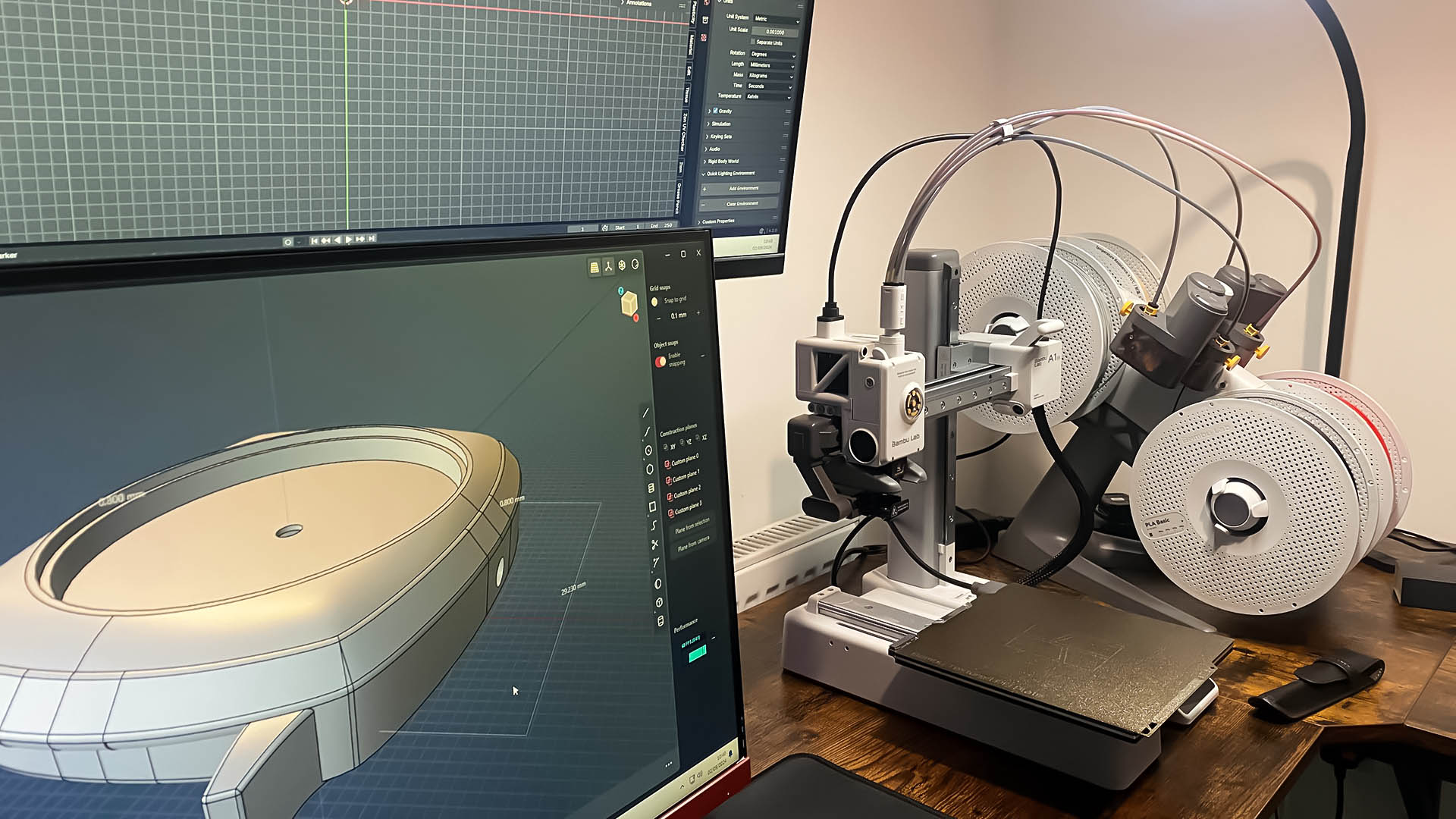

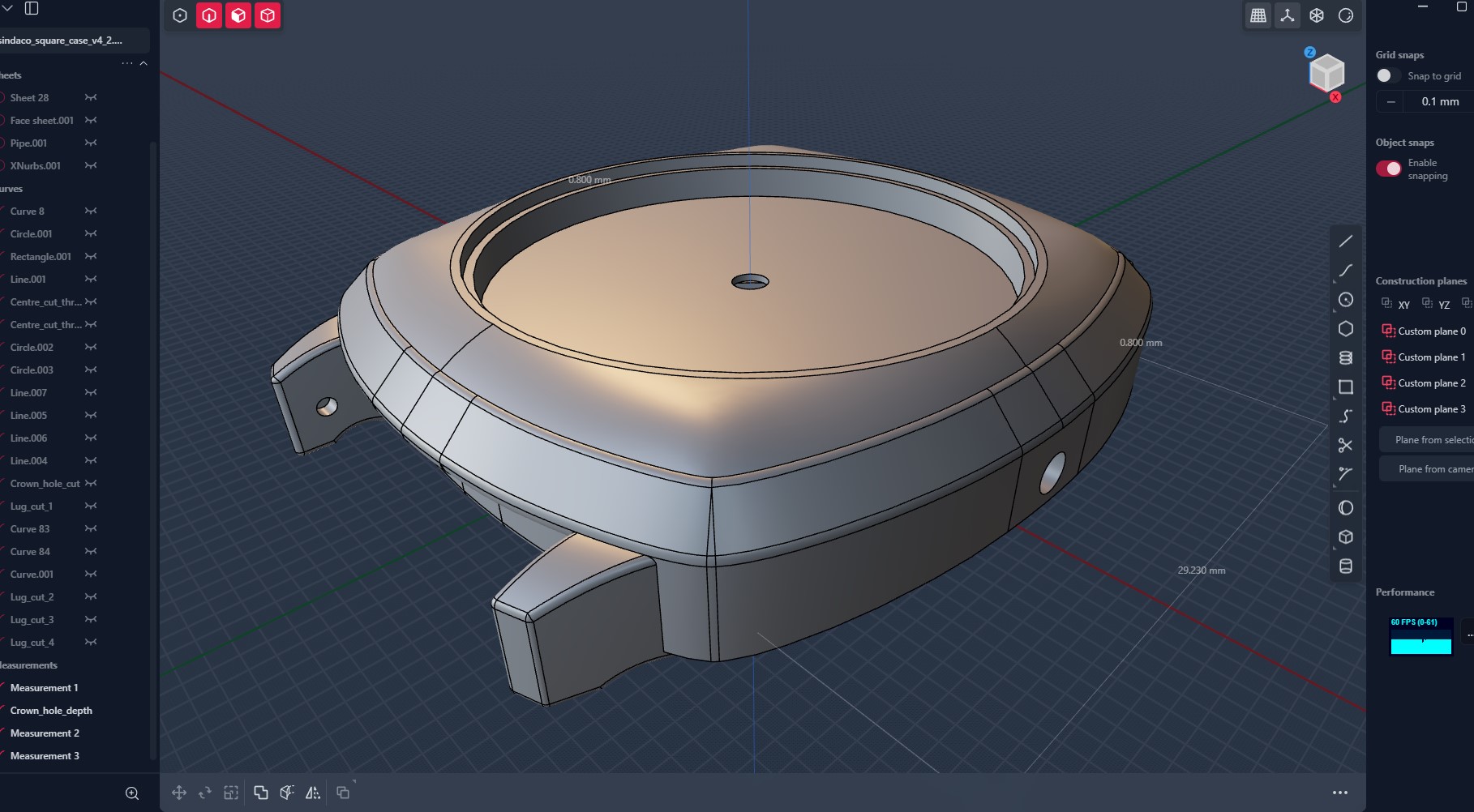

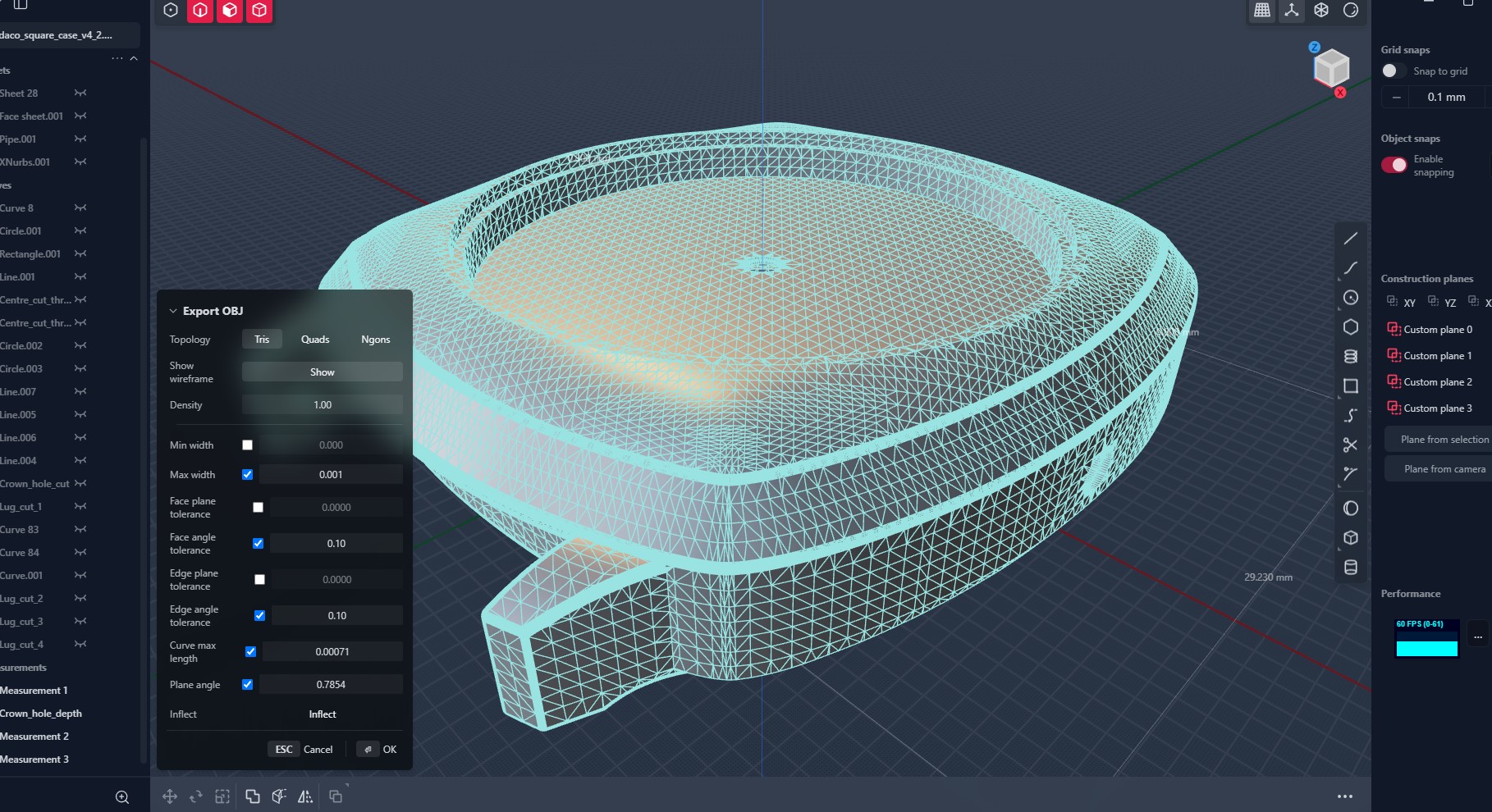

The Bambu Lab A1 Mini is a new desktop additive manufacturing 3D printer, and it is an excellent piece of equipment, in my opinion. My Bambu Lab A1 Mini sits almost next to me on my desktop, ready to print any design I am working on☕. It is perfect for me, so I can handle, test, and feel any watch case design, or any other design for that matter, that I have built in my Plasticity 3D CAD software or Blender software, before it goes off for final manufacture in its metal guise. This 3D printer has revolutionized the way I bring my ideas to life, allowing me to experiment with intricate designs and produce prototypes with remarkable precision. The convenience of having it right on my desk has been a game-changer, as I can easily iterate through different iterations of my designs without any hassle, making necessary changes if I need to quickly. Additionally, the compatibility with various software tools ensures seamless integration into my existing workflow, making the printing process a seamless and enjoyable experience. The Bambu Lab A1 Mini has truly elevated my creative process and empowered me to explore the boundaries of additive manufacturing.

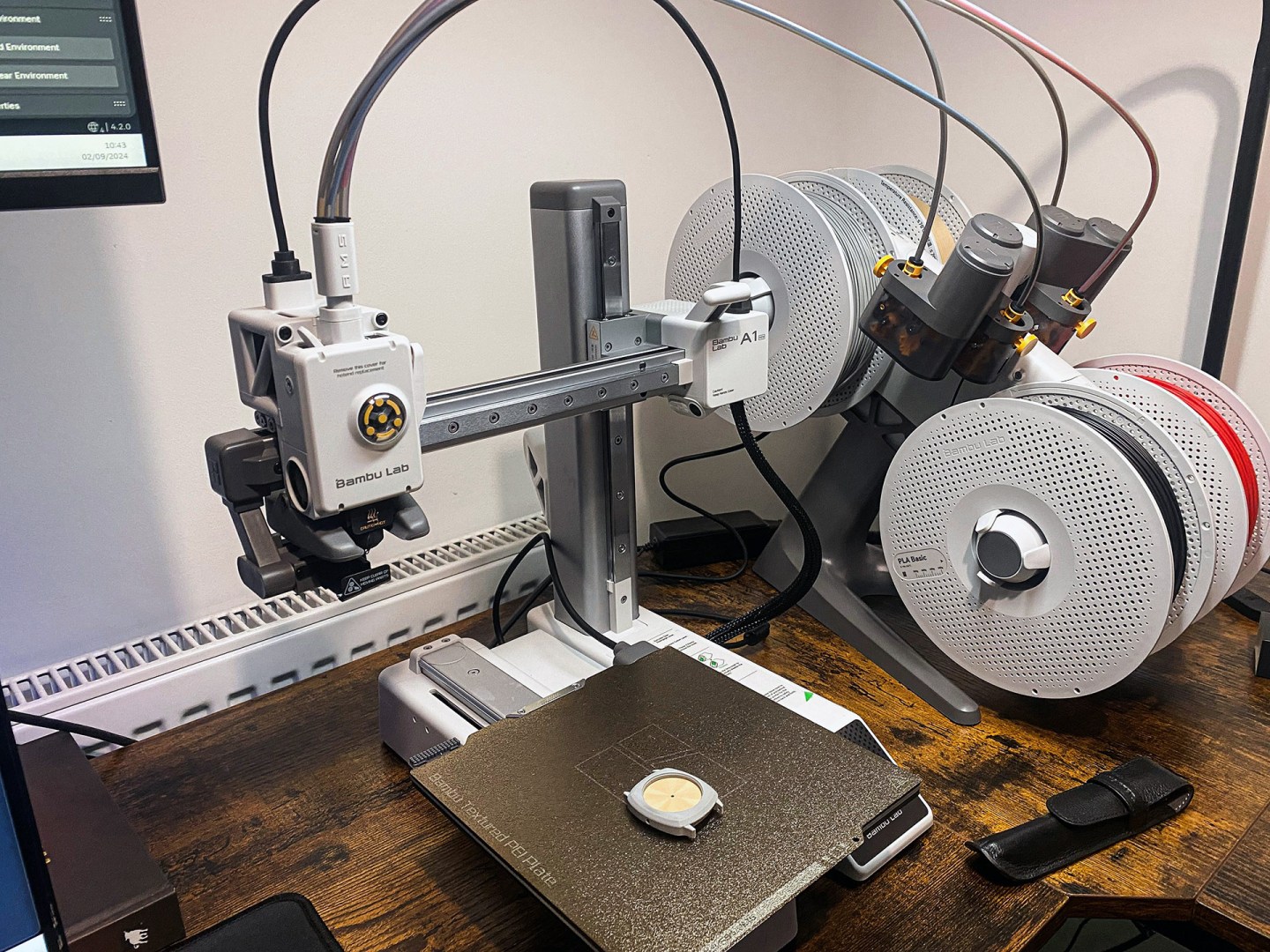

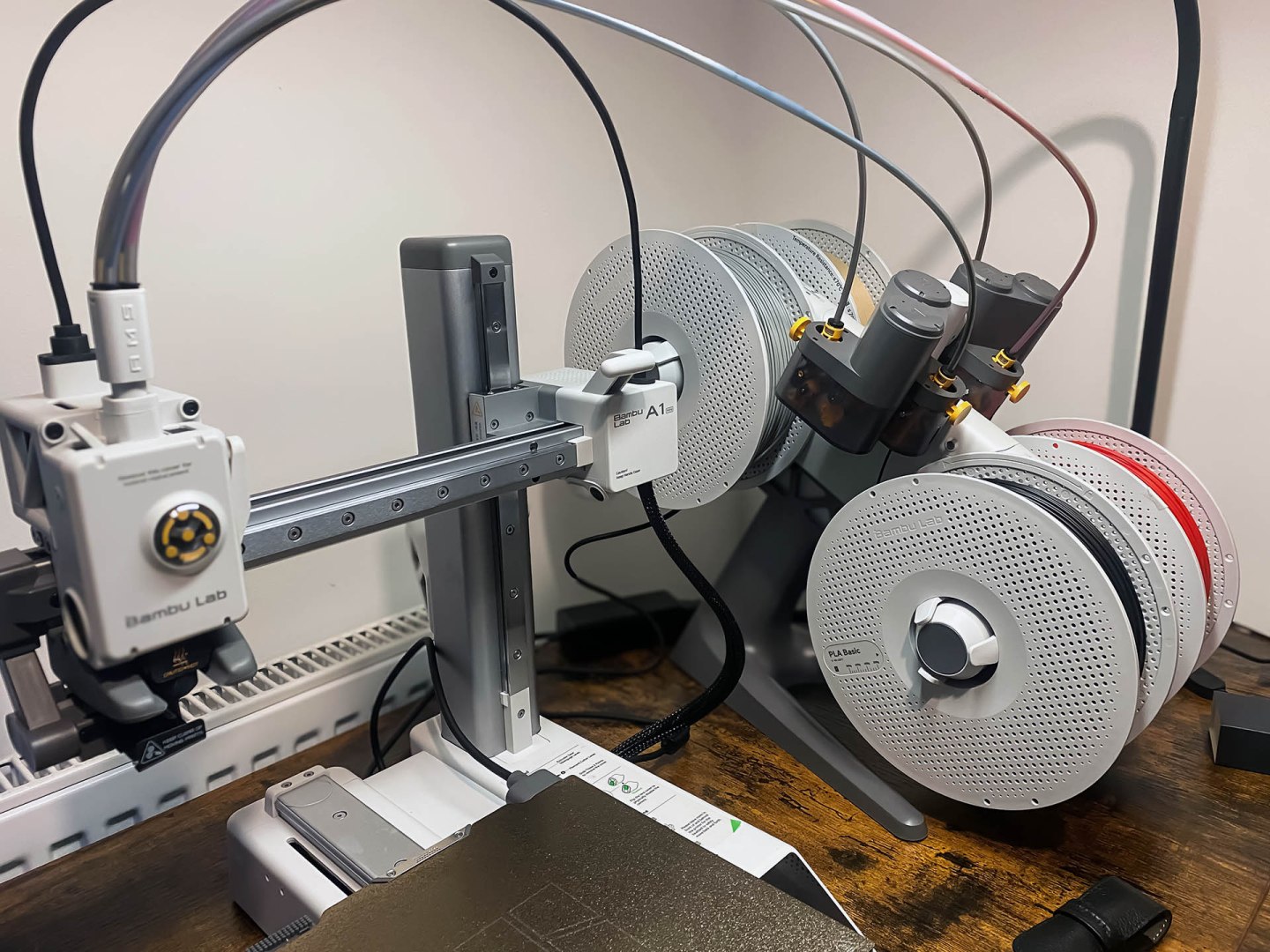

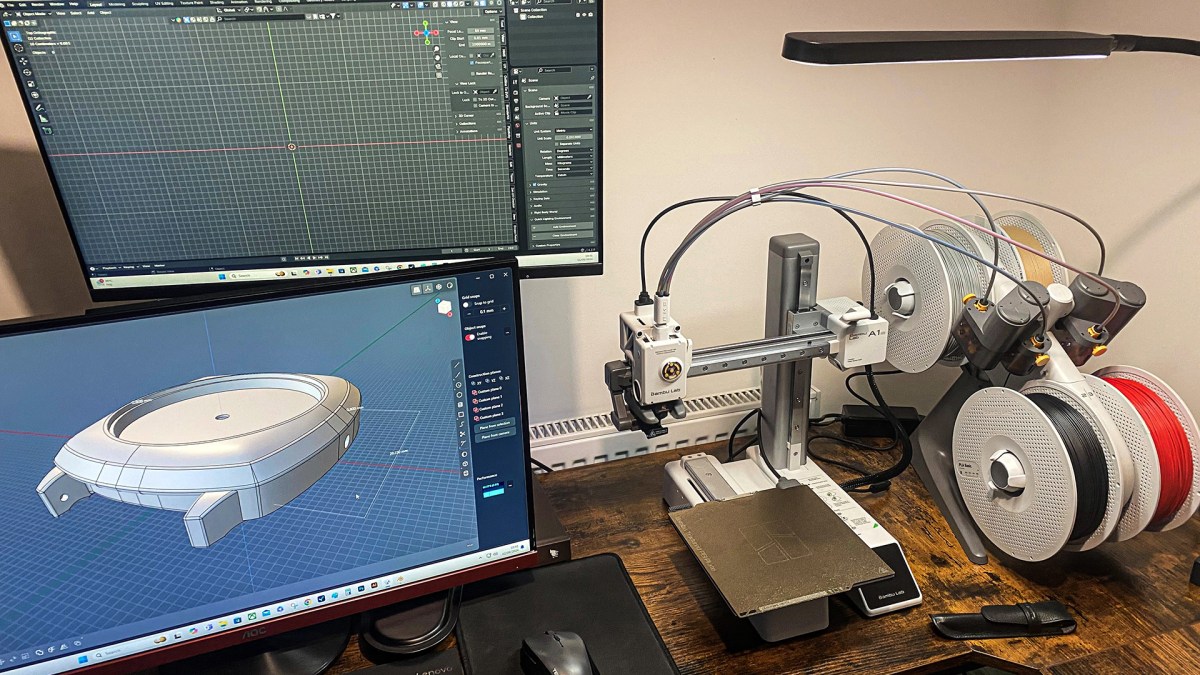

My Bambu Labs A1 Mini Printer Desktop:

The Bambu Lab A1 Mini 3D printer, with its sleek and compact design, is an ideal choice for anyone working with limited space or needing a portable 3D printing solution. The print size volume is approximately 7 inches x 7 inches, which is plenty for me, especially as I mainly design small objects, but Its small footprint doesn’t compromise on performance at all, as it consistently delivers exceptional printing capabilities with high precision and quality results. It is also very fast👍! With the ability to print up to 500 millimeters per second. Whether you are a novice or an experienced professional, you will appreciate the user-friendly nature of this printer, from its straightforward setup to its intuitive operation. The versatility and reliability of the Bambu Lab A1 Mini 3D printer make it a valuable asset for a wide range of 3D printing projects, allowing users to bring their creative ideas to life with ease and efficiency.

The Bambu Lab A1 Mini 3D printer is a cutting-edge device that represents the pinnacle of technological advancement in the field of desktop 3D printing. Its impressive technical features are designed to meet the needs of professionals and enthusiasts alike. With a high precision printing capability, boasting a layer resolution as fine as 0.08 mm to 0.28 mm, this printer ensures that every intricate detail of the design is captured with accuracy. Though I only tend to print my models in PLA Plastic, this printer is capable of working with PLA, ABS, PETG, ASA, and more, enabling users to explore and create a wide range of objects with different properties and characteristics.

A watch case design I am working on:

Converting the design to triangles to print:

This 3D printer is so easy to use too! It is pretty much ready to go out of the box. All you need to do is take a few supporting screws out, remove the packaging, plug it is and you are ready to go! Upon turning the Bambu Lab A1 Mini on, it will set itself up for the space you have it working on. It will go through series of calibration checks, even running a motor noise check algorithm; it will check the noise of the motors while running and essentially quieten itself down, so you almost can’t hear the servo motors running! How clever is that🙂? It will run vibration checks, that compensate the vibration depending on the workspace you have it on, very clever. Because of all this clever calibration it produces stunning and clean prints pretty much all of the time.

The printed prototype watch case in PLA plastic:

The printer can also print in 4 colours using the Bambu Lab AMS Lite filament feed system. The Bambu Lab AMS Lite filament feed system sits next to the printer and can feed 4 separate coloured filaments into the printer, enabling you to print off your model in 4 colours, How cool is that🙂? It is designed to provide smooth and reliable feeding of filament, and It features a durable and lightweight design allowing for easy installation and operation. This feed system seems to work flawlessly and has never let me down or jammed at all. It is known for its precision and consistency, ensuring that the filament is fed evenly and without any jams or interruptions during the printing process.

A few watch case design prototypes printed:

The AMS-Lite feed system to the right:

If you are looking for a great desktop printer, especially for prototyping, or any other 3D printing for that matter, I can highly recommend this one. You would struggle to go wrong!👍.

Have a great day good people😊.

Kind regards, Jay

Discover more from Jayargonaut - Watch Designer

Subscribe to get the latest posts sent to your email.

Cool gizmo you got there!

LikeLiked by 4 people

It certainly is a great gizmo Ajinkya👍. They are wonderful machines that produce great results, and great value too! If it is area you have an interest in, I would certainly recommend this model. Kind regards…Jay😊

LikeLiked by 3 people

Thanks for the recommendation Jay, cheers!

LikeLiked by 3 people

You are very welcome Ajinkya😊

LikeLiked by 3 people

Wow, that is great Jay, enjoy your design.

LikeLiked by 3 people

Thank you Freddie😊, glad you liked the post. I love this stuff, in fact you could say I am a bit obsessed with it maybe😄. Hope you are keeping all well my friend👍. Best, Jay

LikeLiked by 3 people

You’re welcome Jay, it’s really good you have the equipment. Have a nice day Jay.

LikeLiked by 2 people

Oh man, this post is super useful, Jay. About a year or so back I was thinking of looking at 3D printers – one of my old coworkers uses one to make designs on Etsy for a side business. Wouldn’t even know where to start! Thanks for sharing 😊 extremely helpful 🙏 ☕️

LikeLiked by 3 people

Hi Laura, glad the post was useful😊👍. Well if it something that interests you I would definitely recommend this model, or the model up, if you wanted something slightly bigger. They are fantastic machines that are the top of their game, and I have done the research! And even if you are not into the designing side that much, there is a whole plethora of ready built designs and models in a huge community. They are an awesome price too, don’t know how they make something so good for such little money to be truthful🤔. Seriously, if you do want any advise in this area, feel free to give me a shout👍. Hope you day is going well…Jay😊☕

LikeLiked by 3 people

Thank you Jay 🙏 I may have to do that, super super appreciated always

LikeLiked by 3 people

Very interesting! I’ve never seen one and wondered how they work. 🙂

LikeLiked by 4 people

Hi MagickMermaid😊. Thank you. I am glad you enjoyed the post and found it interesting. Kind regards…Jay😊

LikeLiked by 3 people

Wow, that is so cool snd convenient. So futuristic as well, right out a Heinlein or Bradbury work 😎

LikeLiked by 2 people

Yes, they are very cool Darryl👍! Very easy to use with brilliant results too. Perfect for a retro-tech geek like me, Exactly…it looks a bit mad-lab with the tubes sticking out doesn’t it. With a bit of Kraftwerk playing in the background, it is hypnotic to watch it work too🙂. Best…Jay✌️

LikeLiked by 3 people

Very interesting Jay. It is a subject that intrigues me though it’s finding time ( and money) to pursue all these things.

LikeLiked by 2 people

Hi Graham. Thank you & glad you found the post interesting👍. I do know what you mean, both of these commodities can be scarce sometimes. What I can say is, if you ever do dip your toe in, this brand has to be one of the best value out there. Best…Jay😊

LikeLiked by 2 people

BUON WEEK-END

LikeLiked by 2 people

You too my friend👍

LikeLiked by 2 people

ok

LikeLiked by 1 person

Egads!

This is fabulous.

Congratulations on such a useful embrace of tech. (First thing I ever heard of using a 3D printer for was a gun)

Cool unit to boot.

I am impressed. Have a fab week Jay!

LikeLiked by 2 people

Thank you Resa. Yes, it is a wonderfully useful piece of tech. Wow, printing guns….it doesn’t surprise me, you can pretty much print anything these days!

Thank you😊…You have an awesome week too Resa✌️

LikeLiked by 3 people

This is just brilliant.

LikeLiked by 4 people

Thank you Kaayee👍. Glad you enjoyed the post. Kind regards…Jay😊

LikeLiked by 2 people

I worked for a very long time with the 3D – CAD OneSpaceDesigner from Hewlett Packard. Before the name was ME30. Professional CAD mostly in companies.

LikeLiked by 1 person

Interesting🤔! Your post sent me off googling OneSpace Designer as I had not used that, or heard of it. It seems it has been around for a long time, but changed over the years in name and form: CoCreate, ME30 as you suggest. I can;t find much about it, but seems it is still used by some companies. I find things like this interesting. A bit like the software called Lightwave 3D software, which was used heavily in the film industry to help create great things like Star Trek Enterprise, and more, in the 90’s, but then fell out of use and became redundant…but has now been bought by a new company and has been updated, re-released, and given new life. Interesting stuff! Thank you for that info👍, I appreciate it😊. Best…Jay

LikeLike

Initially, I was elated with this your description of this unit . . . then I started looking into PLA, ABS, PETG, ASA, and other materials.

That dampened my enthusiasm considerably.

I’m primarily interested in making useful items, and PLA (which seems to be the easiest to work with) doesn’t seem well suited for anything that involves loads or exposure to the environment.

Unfortunately, the plastic that are suited are difficult to work with and often require enclosures, heaters, good ventilation, etc.

The recommendation for PLA is to keep the material in a vacuum sealed bad, preferably with a desiccant. Which has me wondering about your set-up.

Are the spools of material mounted only when you need them, and stored in a controlled environment when not used?

Just out of curiosity, how much would those four spools cost?

Looking at the prototypes, it looks as if they would need smoothing or sanding. Aside that, just how fragile are they?

If you answer, don’t waste too much time doing so. I’m just looking for general information at this point.

But, as an aside, do you ever print with other materials to make usable items?

Thanks for any information you can provide.

LikeLike

Hi Emilio😊. You post was sat in pending (new comment I guess), hence you will see it now. Thanks for your questions, I will try to answer them to my best current knowledge as I can.

As with many things in life, we often over-engineer in our minds, and google can lead us to doing this, similar to over diagnosing. I fall victim to it too. PLA is not the strongest, nor most weather resistant, but is by no means weak. And the tougher materials are just harder to work with, but not necessarily hard. PLA is great material, but not a replacement for metal engineering parts. But for general useful parts, it is great, and for prototypes too. Tougher materials just tend to need higher temperature to print. Also new materials are being developed all the time.

But PLA is great, it is generally strong, just more harder and more brittle than say ABS.

PLA being organic based is more prone to absorbing moisture, but again, this doesn’t mean it just gets immediately damp, just in comparison with ABS, which is petroleum based, it is more prone to absorbing moisture. My spools of PLA sit on the machine all the time with no problems, I live in the UK, my house is fairly new with good insulation, my set up is fine. If your machine was in a damp shed or garage say, then maybe there would be a case for that, I am not sure, but then it can always be dried.

As with all 3D printing, some finishing might be required, depending on your taste and requirement. For me I am mostly prototyping, so a small amount of fettling or filing might be required from the support tags, other than that the finish is good for me. It is basically plastic so expect it to like working with such, quite easy👍.

spools are generally £13-£20 each for 1kg of raw material, some materials more. For me this lasts a long time as I am generally making small parts.

No, my parts are not fragile, PLA is used in some consumer goods, it is just not as flexible as say ABS or PETG…maybe PETG would be good for you.

No, I only use PLA as it is good enough for me👍. maybe in the future, but for now PLA is easy, strong, and durable for me.

I hope this helps Emilio. The Bambu Labs are great machines, easy to use with user friendly software, and easy on the budget. with the A1 mini you can literally print almost straight out of the box.

Always happy to help and discuss😊.

Kind regards, Jay

LikeLike

Thank you, that really helps.

LikeLike

On the concept of finish of 3D prints, and to further embellish on what I said in my reply: I learnt about ‘fuzz’ or ‘fuzzy’ finish that you can apply with your 3D printer, and is easy to apply in the Bambu Labs software. Personally, for what I am doing mostly, I don’t need it, but it applies a fuzz skin finish to your 3D prints, for which you can determine the parameters. Here are two great youtube videos from two great makers that go into this concept in detail, and describe how you can achieve consumer friendly finishes with your 3D printer. Enjoy😊:

LikeLike

Also very useful as the fuzzy finish looks a lot better to me than the other.

Are you going to employ it for your prototypes?

LikeLiked by 1 person

I might employ the fuzzy skin in some circumstances. One thing to note is that it makes the print run time longer and alters the size parameters very slightly, so if you have a size tolerance you might have to just factor this in.

LikeLiked by 1 person

Wait . . . Is that a feature of the printer (and printer software), or of the 3D modelling software?

LikeLiked by 1 person

Yes you are right Emilio, it is a feature of the printer and the printers software. It is very easy to implement, essentially you just turn that option on and set the size parameters. Very easy.

LikeLiked by 1 person

Hmm . . . I left a comment, but I don’t see it. Before I try again, I’ll wait to see if it appears.

LikeLiked by 1 person

Very interesting! I like seeing the prototypes and how it goes from your computer screen to something tangible. Amazing…

LikeLiked by 1 person

Thank you Catherine😊. I am glad you enjoyed the post and found it interesting😊. Kind regards…Jay

LikeLiked by 1 person

SALUTI

LikeLike

😉👏🏻It’s a fantastic job!

LikeLiked by 2 people

Thank you, It certainly is😊. And thank you for your great comment👍. Kind regards…Jay

LikeLiked by 1 person

😉

LikeLiked by 1 person